A Scratch-Building Experiment

I decided that it would be very satisfying to try to build a model completely from scratch — something I have never tried before. The challenge would be to create a flyable model, despite being a relative newcomer to this hobby. These days, aircraft can be constructed from a variety of lightweight materials. For this project, I decided to use traditional balsa construction, covered with monokote. This would be blazing new trails for me — sort of. I have, of course, built a few planes from kits which included pre-cut balsa parts, but it’s been awhile. In fact, the last time I did this was about 44 years ago, when the current technology included a slow-drying glue, lots of straight pins, and tissue paper for the “skin”. This time, I won’t have the benefit of pre-cut parts, so I’d need to make them myself. Modern technology gives a big boost to the construction process with instant-bonding cyanoacrylate glue (Superglue) and a mylar-type covering that “shrink-wraps” to the model. The challenge was to build something lightweight enough to fly well while maintaining a sturdiness to withstand potential crashes.

Sunday, September 23

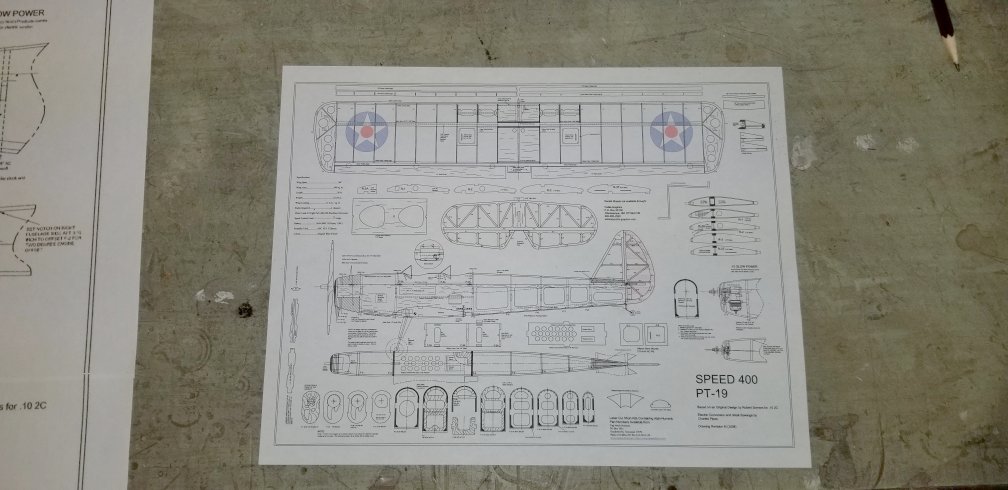

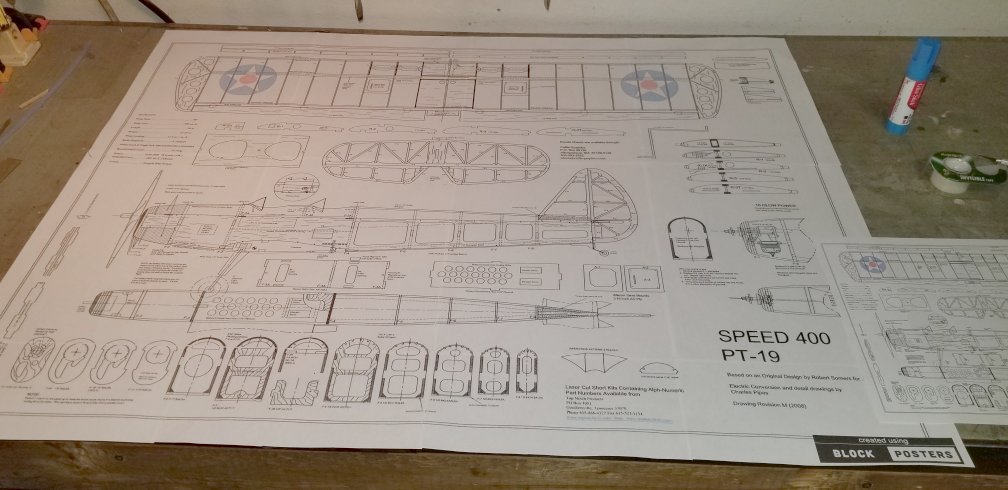

Even though I had sheets of balsa and basswood to create the necessary parts, I needed a full-size plan to ensure that the shape and proportions are accurate. There are plans for RC aircraft all over the World Wide Web; I wanted one that was interesting and not too complicated. After checking out several possibilities, I decided on a Fairchild PT-19 Cornell — a WWII-era trainer.

An Internet search for a plan unearthed several possibilities and I chose one that seemed to be clear and straightforward, from a 2013 Model Aviation Magazine article.

Of course, if I used the original PDF printout to build on, the wingspan would be only 9 inches — not practical for this purpose but might be an interesting future challenge. [ I later realized that the downloaded PDF plan was already to scale but I didn’t choose the correct setting during printing. Oh, well — live and learn!] Years ago, I had been introduced to a website called Block Posters, a free service that could take any image and blow it up to almost any size. I only needed to glue and tape the multiple sheets together to create the full-size plan. The model in the article has a wingspan of 40″, but I decided that a 27″ wingspan (1/16 scale) would make the model a little easier to lug around.

I then prepped my workshop for model building, consolidating my stash of balsa and basswood.

Monday, September 24

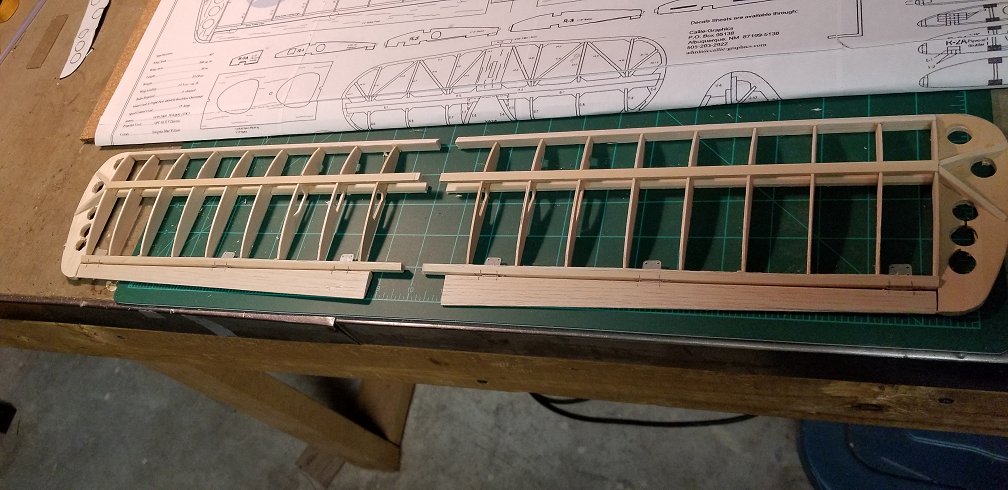

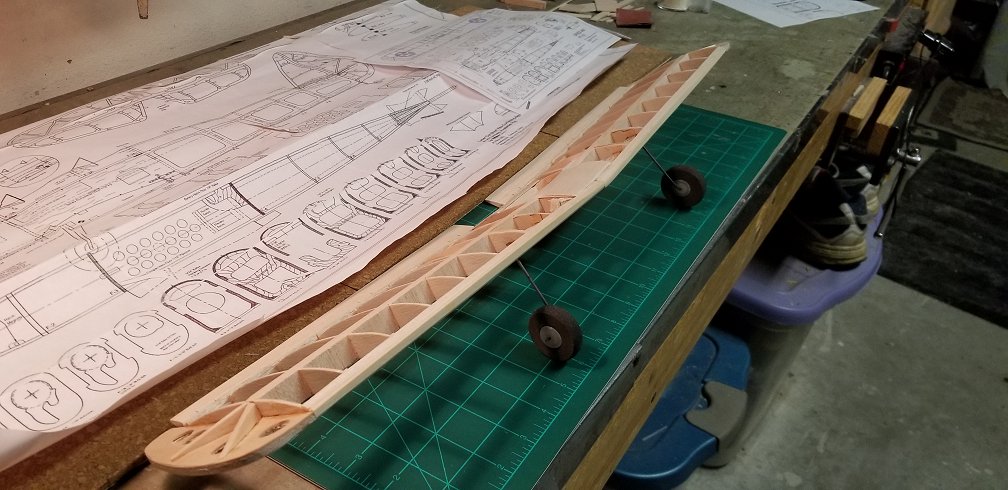

Building the Wing

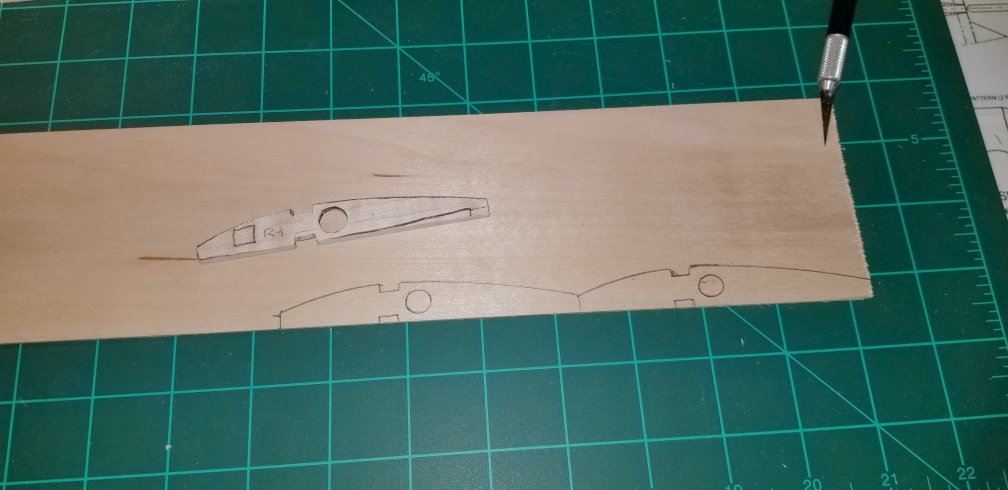

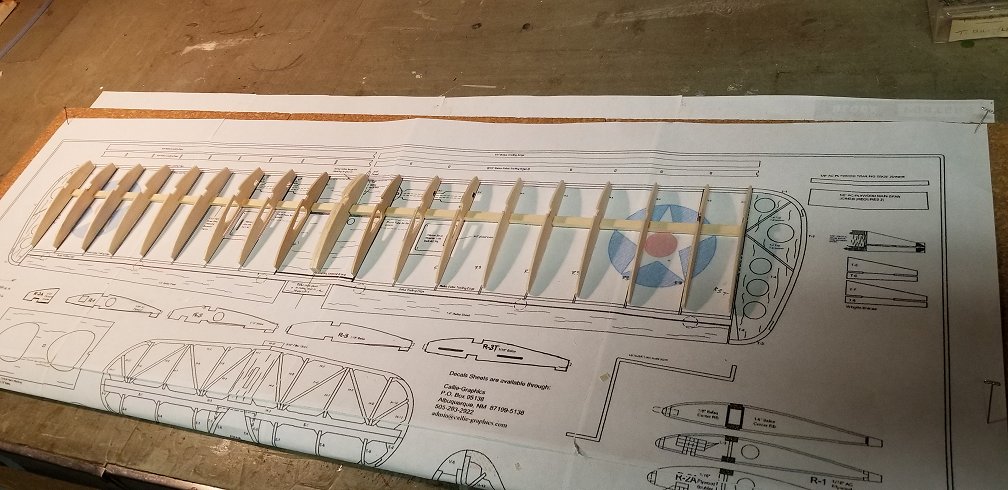

Again, this was the very first time I have created a model that didn’t have parts already cut out, so I had to problem-solve from the get-go. I was reluctant to cut up my plans, so I used carbon paper to transfer the designs onto the wood. I started with the wing.

This really took me back–the last time I did this, I was a teenager in high school. The nostalgia was enhanced by my background music from the 70’s, although it’s from SiriusXM instead of an AM radio station.

Tuesday, September 25

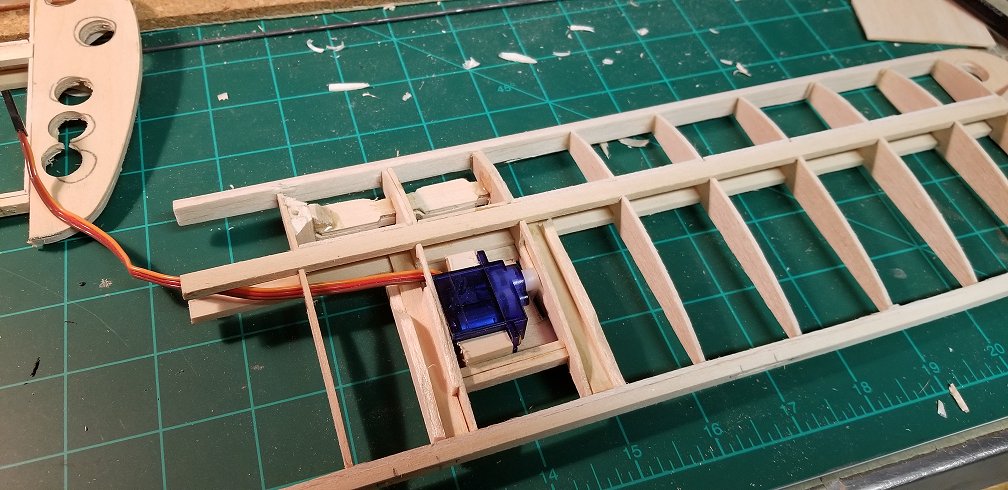

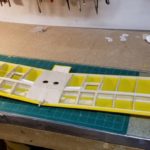

Bracing was added and the ailerons. I had quite a few plastic hinges that I’d been saving for years and found an old hinge tool that enabled me to make the necessary slots for the aileron hinges.

I also built the hatches that would house the micro servos.

Wednesday, September 26

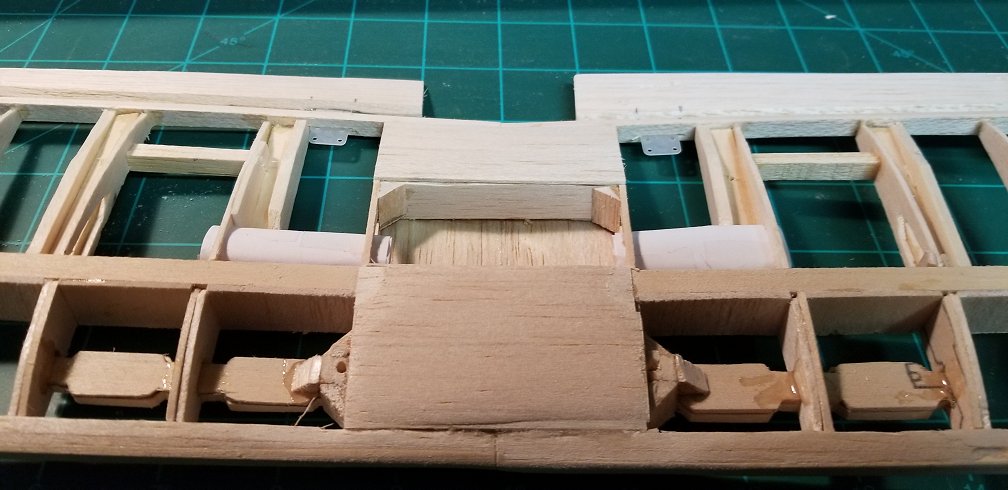

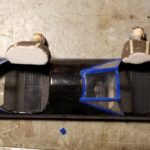

With the basics of the wing complete, the next system to work on was the landing gear and supports. For the gear, it was necessary to reinforce the wing ribs that would be stressed by the act of landing. I also needed to secure these areas with epoxy for additional strength. I attached the parts that set the dihedral and glued together the left and right wings.

The gears are 1/8th inch wires that I bent to match the design on the plan.

Friday, September 28

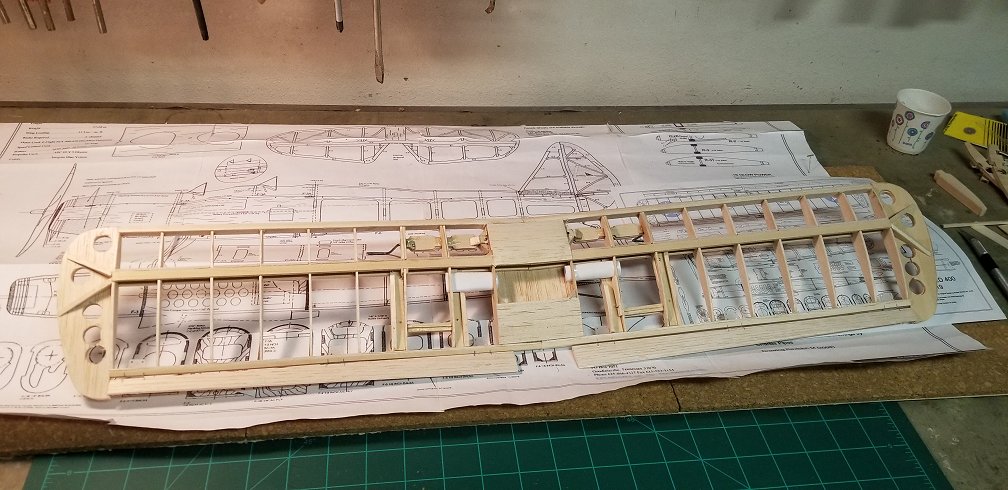

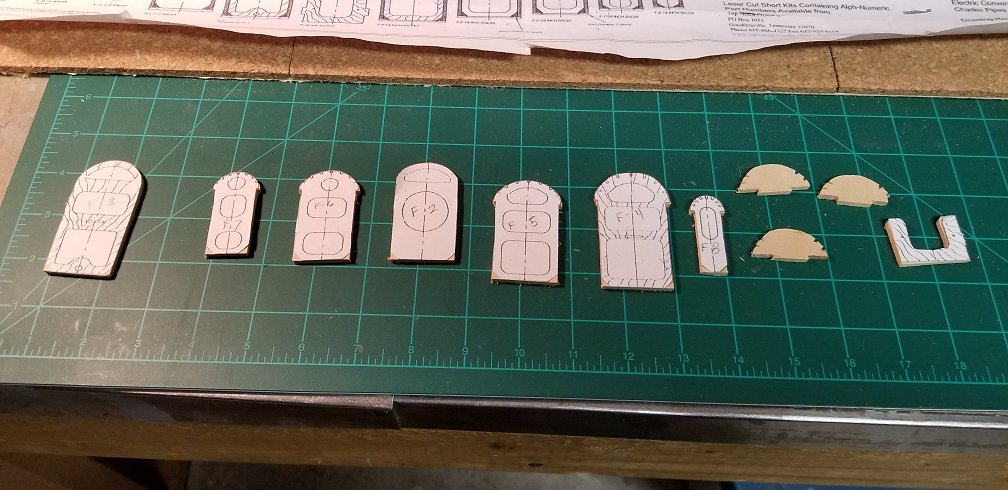

With the wings mostly done, it was time to start on the fuselage. I didn’t like the carbon-paper method of copying the parts, so I decided to go ahead and cut out the pieces from the plan and stick it on the wood for a cutting guide. I still wanted to keep the main plan intact, so I made a copy of the section I needed and cut out those parts, attaching them to the balsa with Scotch Restickable glue stick..

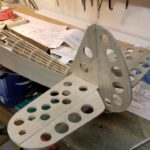

I peeled off the guides and cut holes to lighten up the pieces.

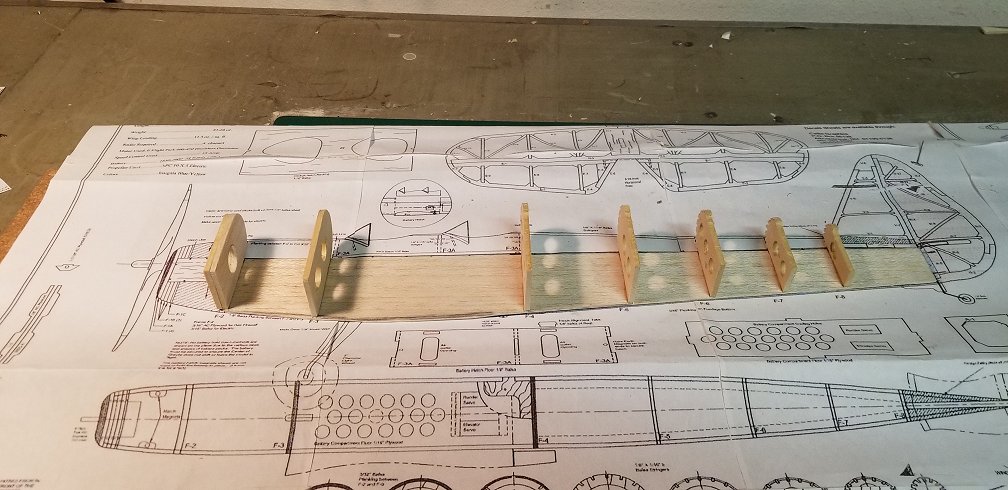

Using the plan, I put the formers in place…

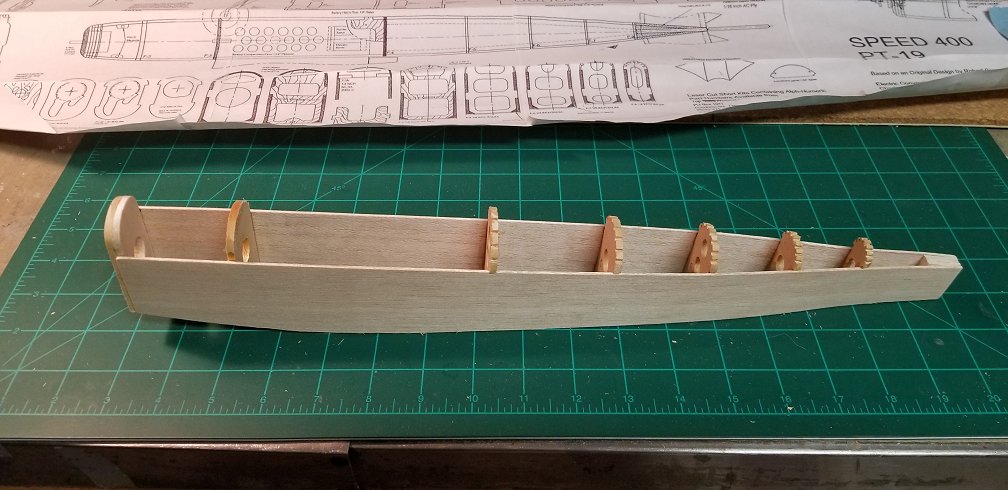

and attached the other side.